Teadmiste baas

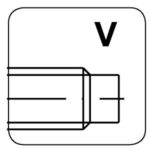

Pea tüübid

Süvendid (täked)

Keerme otsatüübid

Materjali tüübid

Kaitsekatted

Elektrolüütilised tsinkkatted

Kromaadi konversioonikatted

Nikli kattekiht

Messingist plaatimine

Fosfaatimine

Oksüdatsioon

Standartite loetelu

Pea tüübid

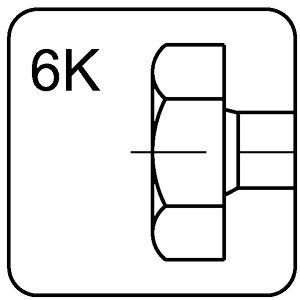

kuuskantpeaga – 6K

kuuskantpeaga – 6K

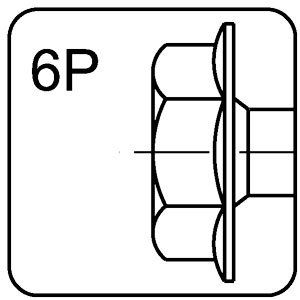

kuuskantpeaga, äärisega – 6P

kuuskantpeaga, äärisega – 6P

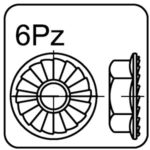

kuuskantpeaga, lukustushammastusäärisega – 6Pz

kuuskantpeaga, lukustushammastusäärisega – 6Pz

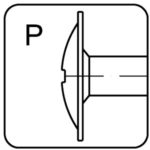

äärisega – P

äärisega – P

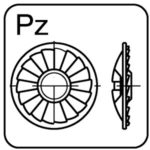

lukustushammastusäärisega – Pz

lukustushammastusäärisega – Pz

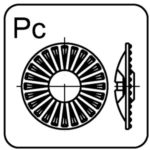

rihveldatud äärikuga – Pc

rihveldatud äärikuga – Pc

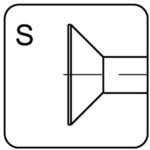

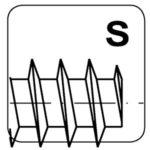

peitpeaga – S

peitpeaga – S

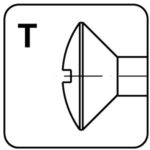

läätspea – T

läätspea – T

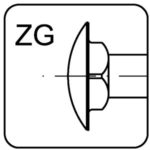

ZG

ZG

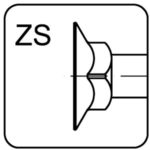

ZS

ZS

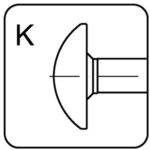

sfääriline -K

sfääriline -K

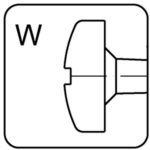

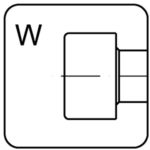

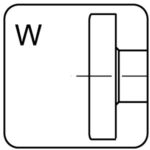

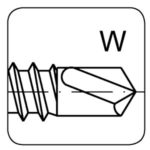

ümarpea – W

ümarpea – W

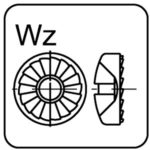

ümarpea, lukustusäärisega – Wz

ümarpea, lukustusäärisega – Wz

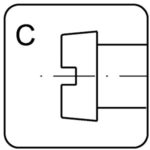

silindriline – C

silindriline – C

nelikant – 4K

nelikant – 4K

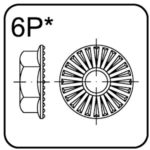

kuuskantpea äärisega ja rihveldusega – 6P*

kuuskantpea äärisega ja rihveldusega – 6P*

Süvendid (täked)

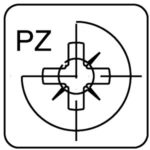

Pozidriv – PZ

Pozidriv – PZ

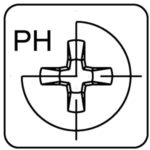

Philips – PH

Philips – PH

ZW

ZW

kombi (Pozidriv) – KOMBI

kombi (Pozidriv) – KOMBI

kombi (Phillips) – KOMBI

kombi (Phillips) – KOMBI

sisekuuskant – IM

sisekuuskant – IM

Torx – TX

Torx – TX

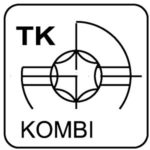

T-KOMBI torx – TK

T-KOMBI torx – TK

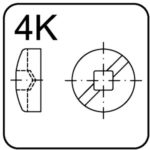

nelikant KOMBI – 4K

nelikant KOMBI – 4K

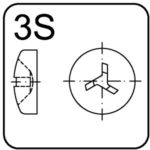

3S

3S

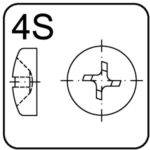

4S

4S

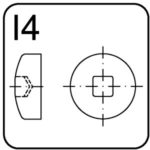

nelikant – I4

nelikant – I4

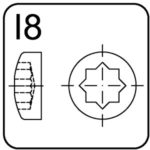

kaheksakant – I8

kaheksakant – I8

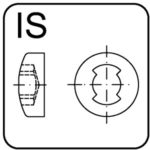

siduriga – IS

siduriga – IS

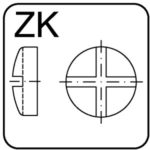

ZK

ZK

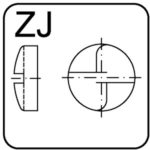

ZJ

ZJ

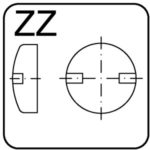

plokščiam atsuktuvui tik užsukimui – ZZ

plokščiam atsuktuvui tik užsukimui – ZZ

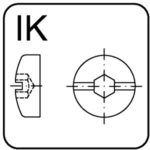

sisekuuskant KOMBI – IK

sisekuuskant KOMBI – IK

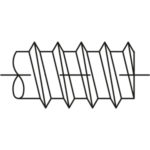

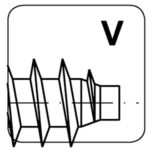

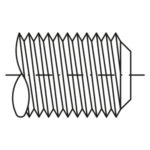

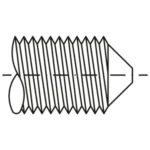

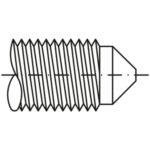

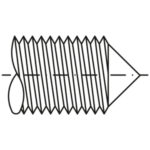

Keerme otsatüübid

| Tehnoloogilised nimetused | Sümbol | Tehnilised joonised | ||

| Meeterkeermega kruvid | Plekikruvid | UNIX, do tworzyw | ||

| Ścięte |  |  |  |  |

| Kasutusjuhend |

|      |  |  |

| Terav |  |  |  |  |

| Puurotsaga kruvi |  |  | ||

| Z wiertnikiem ze skrzydełkami |  |  | ||

Materjali tüübid

teras

teras

karastatud

karastatud

roostevaba

roostevaba

happekindel

happekindel

alumiiniumi sulam

alumiiniumi sulam

alumiiniumi sulam

alumiiniumi sulam

mosiądz

mosiądz

vask

vask

alumiinium

alumiinium

EPDM kumm

EPDM kumm

polüetüleen

polüetüleen

polüpropüleen

polüpropüleen

polüamiid

polüamiid

PVC plastik (polüvinüülkloriid)

PVC plastik (polüvinüülkloriid)

Kaitsekatted

powłoka cynkowa

powłoka cynkowa

tsink 5 µm, 8 µm, 12 µm

tsink 5 µm, 8 µm, 12 µm

kollane tsink

kollane tsink

valge tsink

valge tsink

must tsink

must tsink

powłoka cynkowa płatkowa Zintec – biała

powłoka cynkowa płatkowa Zintec – biała

hõbedane tsink

hõbedane tsink

nikkel

nikkel

messing

messing

oksydowanie

oksydowanie

fosforanowanie

fosforanowanie

ocynk ogniowy

ocynk ogniowy

Geomet

Geomet

powłoka cynkowa płatkowa Zintec – czarna

powłoka cynkowa płatkowa Zintec – czarna

powłoka Brunierowana

powłoka Brunierowana

Elektrolüütilised tsinkkatted

Electrolytic zinc coatings are commonly used protective coatings. The anti-corrosive properties of these coatings depend to a great extent on their thickness. The standard thickness of zinc coating we use during the production is 5pm. We also offer other thicknesses per Client’s request.

When choosing the thickness of the coating, you must take into account additional damaging factors, like: condensation of water vapour, the presence of damaging gases and vapours, the presence of electrolyte solutions, dust and sand.

The physical, chemical and mechanical properties of zinc coatings have an influence on products’

performance characteristics. These properties limit the use of coatings in the food industry and for

products requiring high hardness of the top coat. In such cases, zinc coatings are replaced with other,

adapted to specific working conditions.

In some cases, specially designed zinc coating technology allows for achieving protective and decorative effects that are especially recommended when high durability of the coating is not required.

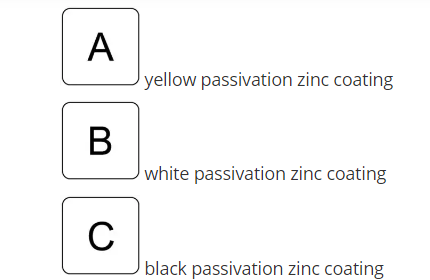

Kromaadi konversioonikatted

In order to increase corrosion protection, zinc coatings are conversion chromated (passivated). Conversion chromating also allows for achieving protective and decorative effects that are especially in cases where high abrasion durability of the coating is not required. For our products, we use a white, yellow and black coating.

Considering the colour of the obtained chromate coatings, it has to be stated that golden-yellow coatings exhibit significantly higher corrosion resistance than clear, colourless coatings.

Chromate coatings have relatively low abrasion resistance. This is especially true for thicker, black coatings. After drying, the abrasion resistance increases. Least susceptible to abrasion are colourless and white coatings.

Nikli kattekiht

Electrolytic nickel coatings are used in engineering for decorative and protective purposes and as technical coatings. For our products, we use decorative and protective coatings which provide optimal protection against corrosion and high aesthetic qualities.

Nickel coatings are used for fasteners are characterised by high resistance to atmospheric corrosion. We offer two types of coatings: – matte for components like euro screws (screws for furniture fittings), – glossy for components like hinges, furniture joints.

Messingist plaatimine

Brasses are copper and zinc alloys. The properties of electrolytic brass-plated coatings vary, depending on the content of the main alloying element, which is zinc. The chemical composition of the coating has also a determining influence on its colour, which varies from red (high copper content) to different shades of gold-yellow. The standard type of brass-plated coatings is yellow.

They are characterised by high aesthetic qualities and protect against corrosion. The anti-corrosion properties of brass-plated coatings allow for use in slightly damaging environments. Years-long analysis of the properties and applications of brass-plated coatings have shown their high rated use in products like ERICSSON nuts.

Fosfaatimine

Standard phosphate coatings on the fixing elements are mat of dark gray to black colour. Typical phosphate coatings on fasteners are matte, with colours ranging from dark grey to black. Phosphate coatings have anti-corrosion properties and additionally increase the adhesion of applied paint coatings. Phosphating is performed for drywall screws (coarse and fine thread, self-drilling).

The specific use of these products excludes the use of zinc coatings which are easily damaged by contact with gypsum. Phosphate coatings not only protect products against corrosion but also reduce friction coefficient and make installation easier.

Oksüdatsioon

Bluing belongs to the group of conversion oxide coatings on steel. These coatings are made of iron oxides. Both the coating structure and its anti-corrosive properties vary, depending on its thickness. The optimal thickness is 0.6 – 0.8 pm. Blued coating optimally combines corrosion resistance in low corrosive conditions with mechanical resistance to, for example, abrasion.

Using them with additional grease protection significantly improves the corrosion resistance of coating and can even improve its durability. Bluing is used for products subject to heat and thermo-chemical treatment. In contrast to galvanisation, it does not reduce mechanical parameters of the top layer. This is particularly important for products with higher mechanical properties.

Standartite loetelu

| DIN | PN | ISO | GOST | Nr Marcopol |

| ISO: ~7380 | 013.01 | |||

| ISO: ~7380 | 013.01a | |||

| ISO: ~7380 | 013.02 | |||

| ISO: ~7380 | 013.02a | |||

| ISO: 15979 | 024.01 | |||

| ISO: 15977 | 024.02 | |||

| ISO: 15980 | 024.04 | |||

| ISO: 15978 | 024.05 | |||

| ISO: 15976 | 024.06 | |||

| ISO: 15973 | 024.07 | |||

| PN: 82501 | 032.01 | |||

| PN: 82501 | 032.02 | |||

| PN-EN 10230-1 | 061.01 | |||

| PN-EN: 13964 | 051.51 – 051.58 | |||

| PN-EN 14545 | 062.01 – 062.04 | |||

| PN-EN 912 | 062.28 – 062.29 | |||

| DIN: 125 | PN: 82005 | ISO: 7089, | ||

| ISO: 7091 | GOST: 11379-68 | 014.01 | ||

| DIN: 127 | PN: 82008 | GOST: 11379-68 | 014.04 | |

| DIN: ~315 | PN: 82439 | GOST: 3032-76 | 015.10 | |

| DIN: ~316 | PN: 82436 | 011.15 | ||

| DIN: 338 | PN: 59601 | 067.01 | ||

| DIN: 338 | PN: 59601 | 067.02 | ||

| DIN: 338 | PN: 59601 | 067.03 | ||

| DIN: 340 | PN: 59601 | 067.04 | ||

| DIN: 340 | PN: 59601 | 067.05 | ||

| DIN: 436 | PN: 82010 | 014.11 | ||

| DIN: 439 | PN: 82153 | ISO: 4035 | 015.03 | |

| DIN: 440 | PN: 82019 | ISO: 7094 | 014.02 | |

| DIN: 551 | 012.05 | |||

| DIN: 553 | 012.06 | |||

| DIN: 557 | 015.31 | |||

| DIN: 562 | 015.30 | |||

| DIN: 571 | PN: 82501 | 032.03 | ||

| DIN: 580 | PN: 82472 | ISO: 3266 | 063.13 | |

| DIN: 582 | 063.14 | |||

| DIN: 603 | PN: 82406 | ISO: 8677 | 011.08 | |

| DIN: 603 | PN: 82406 | ISO: 8677 | 011.09 | |

| DIN: 605 | PN: 82402 | 011.10 | ||

| DIN: 605 | PN: 82402 | 011.11 | ||

| DIN: ~689 | ISO: ~1677-2 | 063.26 | ||

| DIN: 741 | EN 13411 | 063.15 | ||

| DIN: ~766 | 063.05 | |||

| DIN: 911 | ISO: 2936 | 049.09 | ||

| DIN: 912 | PN: 82302 | ISO: 4762 | GOST: 11738-84 | 011.06 |

| DIN: 912 | PN: 82302 | ISO: 4762 | GOST: 11738-84 | 011.07 |

| DIN: 913 | PN: 82314 | ISO: 4026 | 012.01 | |

| DIN: 914 | PN: 82315 | ISO: 4027 | 012.02 | |

| DIN: 915 | PN: 82316 | ISO: 4028 | 012.03 | |

| DIN: 916 | 012.04 | |||

| DIN: 928 | 015.20 | |||

| DIN: 929 | PN: 82169 | 015.21 | ||

| DIN: 931 | PN: 82101 | ISO: 4014 | GOST: 7798-70 | 011.02 |

| DIN: 933 | PN: 82105 | ISO: 4017 | GOST: 7798-70 | 011.01 |

| DIN: 934 | PN: 82144 | ISO: 4032 | 015.01 | |

| DIN: 960 | PN: 82101 | ISO: 8765 | 011.13 | |

| DIN: 961 | PN: 82105 | ISO: 8676 | 011.12 | |

| DIN: 965 | PN: 82208 | ISO: 7046 | 013.06 | |

| DIN: 965 | PN: 82208 | ISO: 7046 | 013.07 | |

| DIN: 966 | PN: 82212 | ISO: 7047 | 013.12 | |

| DIN: 966 | PN: 82212 | ISO: 7047 | 013.13 | |

| DIN: 967 | 013.03 – 013.05 | |||

| DIN: ~968 | 023.07 | |||

| DIN: 968 | 023.05 | |||

| DIN: 975 | 053.52 | |||

| DIN: 976 | 038.01 | |||

| DIN: 976-1 | 053.52 | |||

| DIN: 985 | PN: 82175 | ISO: 7040 | 015.04 | |

| DIN: 1480 | 063.08-063.09 | |||

| DIN: 1480 | 063.12 | |||

| DIN: 1480 | 063.28 | |||

| DIN: 1587 | PN: 82181 | 015.09 | ||

| DIN: 3050 | 063.02 | |||

| DIN: 3052 | 063.01 | |||

| DIN: 3053 | 063.02 | |||

| DIN: 3055 | 063.01 | |||

| DIN: 3060 | 063.01 – 063.02 | |||

| DIN: 3066 | 063.01 | |||

| DIN: 3127 | 049.04 | |||

| DIN: 3128 | 049.01 | |||

| DIN: 3128 | 049.02 | |||

| DIN: 5299C | 063.23 | |||

| DIN: 5299D | 063.24 | |||

| DIN: ~5685A | 063.05 | |||

| DIN: 5685A | 063.06 | |||

| DIN: 5685C | 063.07 | |||

| DIN: 6334 | PN: 82157 | 015.02 | ||

| DIN: 6379 | PN-M-82137 | 038.02 | ||

| DIN: 6797J | PN: 82023 | 014.05 | ||

| DIN: 6798A | PN: 82024 | 014.06 | ||

| DIN: 6798J | PN: 82023 | 014.05 | ||

| DIN: 6798V | PN: 82025 | 014.07 | ||

| DIN: 6899 | PN: 80247 | EN 13411 | 063.25 | |

| DIN: 6914 | PN-EN: 14399-4 | 011.33 | ||

| DIN:6915 | PN-EN: 14399-4 | 015.33 | ||

| DIN: 6916 | PN-EN: 14399-6 | 014.33 | ||

| DIN: ~6921 | ~PN-EN 1665 | |||

| ~PN-EN 1662 | ||||

| ~PN: 82247 | 011.03 | |||

| DIN: ~6921 | ~PN-EN 1665 ~PN-EN 1662 | |||

| ~PN: 82247 | 011.04 | |||

| DIN: ~6921 | ~PN-EN 1665 ~PN-EN 1662 | |||

| ~PN: 82247 | 011.05 | |||

| DIN: ~6923 | ISO: ~1661 | 015.06 | ||

| DIN: 6923 | PN: 82168 | |||

| PN-EN: 1661 | 015.05 | |||

| DIN: 6928 | ISO: 7053 | 023.02 | ||

| DIN: ~6928 | ISO: ~7053 | 023.04 | ||

| DIN: 7426 | 049.03 | |||

| DIN: 7500 | 021.02 – 021.05 | |||

| DIN: 7500 | 021.09 | |||

| DIN: 7500 CE | 021.08 | |||

| DIN: 7500 DE | 021.01 | |||

| DIN: 7500 ME | 021.06 | |||

| DIN: 7500 NE | 021.07 | |||

| DIN: 7504K | ISO: 15480 | 023.03 | ||

| DIN: 7504N | ISO: 15481 | 023.12 | ||

| DIN: 7504P | ISO: 15482 | 023.09 | ||

| DIN: 7513 | 022.02 | |||

| DIN: 7513 | 022.03 | |||

| DIN: 7513 A | 022.01 | |||

| DIN: 7516 | 022.04 | |||

| DIN: 7516 | 022.05 | |||

| DIN: 7516 AE | 022.08 | |||

| DIN: 7516 AE | 022.09 | |||

| DIN: 7516 DE | 022.06 | |||

| DIN: 7516 EE | 022.07 | |||

| DIN: ~7540 | ISO: ~1677-2 | 063.26 | ||

| DIN: 7965 | 015.14 | |||

| DIN: 7976 | PN: 83101 | ISO: 1479 | 023.01 | |

| DIN: ~7981 | PN: ~83116 | ISO: ~7049 | 023.13 | |

| DIN: 7981 | PN: 83116 | ISO: 7049 | 023.11 | |

| DIN: 7982 | PN: 83114 | ISO: 7050 | 023.08 | |

| DIN: 7983 | PN: 83115 | ISO: 7051 | 023.10 | |

| DIN: 7985 | PN: 82202 | ISO: 7045 | 013.14 | |

| DIN: 7985 | PN: 82202 | ISO: 7045 | 013.15 | |

| DIN: 7985 | PN: 82202 | ISO: 7045 | 013.18 | |

| DIN: ~7991 | ISO: ~10642 | 013.10 | ||

| DIN: ~7991 | ISO: ~10642 | 013.11 | ||

| DIN: 7991 | ISO: 10642 | 013.08 | ||

| DIN: 7991 | ISO: 10642 | 013.09 | ||

| DIN: 9021 | PN: 82030 | ISO: 7093 | 014.03 | |

| DIN: 68163 | 061.02 | |||

| DIN: 82101 | PN: 84703 | 063.22 |